Understanding Torque Converters: The Essential Components And Their Functions

The Marvel of Torque Converters: How They Transform Power

What is a Torque Converter and Why Does It Matter?

A torque converter is an essential component found in vehicles equipped with automatic transmissions. It acts as a fluid coupling between the engine and the transmission, allowing for the seamless transfer of power from the engine to the wheels. The primary function of a torque converter is to multiply engine torque during acceleration, which is particularly beneficial in scenarios where power delivery needs to be smooth and responsive without the need for a manual clutch system. The torque converter not only enhances the driving experience by improving acceleration but also contributes to overall fuel efficiency, making it a vital component in modern automotive engineering.

The Science Behind Torque Conversion: A Simple Breakdown

At the heart of the torque converter’s efficacy lies the principle of fluid dynamics. It consists of three main components: the impeller, turbine, and stator. The impeller is connected to the engine and spins with it, drawing in transmission fluid through a one-way valve. As fluid is flung outward by the impeller, it travels toward the turbine, which is connected to the transmission and rotates as a result. This interaction of fluid creates a torque multiplication effect — the turbine spins faster than the impeller when acceleration occurs, generating additional torque. Moreover, during lower engine speeds, the torque converter allows for slippage between the impeller and the turbine, which facilitates smooth starts without stalling the engine. Understanding this fluid dynamic process helps clarify why torque converters are crucial for maintaining performance while ensuring driver comfort.

Real-World Applications: Where You’ll Find Torque Converters in Action

Torque converters are ubiquitous in the automotive industry, particularly in vehicles that utilize automatic transmissions. Their applications range from everyday cars and trucks to performance vehicles and heavy-duty machinery. In passenger cars, the torque converter enables a smoother transition of power, allowing for an effortless driving experience during city commutes or long highway drives. Harder-wearing applications, such as those found in construction equipment, rely on torque converters to manage heavy loads and provide enhanced torque for demanding tasks. Additionally, the growing interest in electric vehicles (EVs) and hybrids has prompted manufacturers to innovate ways to incorporate advanced torque converter designs, improving efficiency while maintaining performance. Torque converters can also be found in various industrial applications, including manufacturing machinery and marine vessels, emphasizing their versatility and critical role in power transfer mechanisms across multiple sectors.

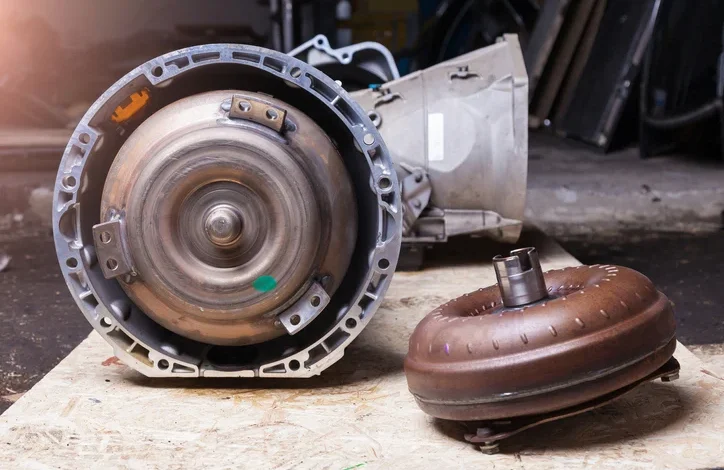

Critical Components: The Anatomy of a Torque Converter

The Stator: The Unsung Hero of Torque Multiplication

The stator is often considered the unsung hero of the torque converter, playing a pivotal role in ensuring that the torque multiplication effect is maximized. Located between the impeller and turbine, the stator is designed to redirect fluid returning from the turbine, allowing it to flow back into the impeller with increased force. When the vehicle is at a standstill or moving slowly, the stator dramatically improves efficiency by eliminating energy loss due to slippage. This important component ensures that power from the engine is effectively utilized, amplifying the torque at lower rpm levels where it’s needed most. The geometry of the stator is crucial, as its design can significantly impact the overall effectiveness of the torque converter, affecting both performance and vehicle responsiveness. Without the stator, the torque conversion process would be inefficient, resulting in sluggish acceleration and subpar fuel economy.

The Impeller and Turbine: A Dance of Energy Transfer

The impeller and turbine work in tandem to facilitate the fluid dynamics that define the torque converter’s operation. The impeller, which is directly connected to the engine, utilizes the engine’s rotational energy to create fluid motion. As it spins, it propels transmission fluid toward the turbine, which is linked to the output shaft of the torque converter and subsequently the transmission. The amount of torque generated depends on the difference in rotational speed between the impeller and the turbine. Under normal acceleration, the turbine is able to turn at a lower speed than the impeller, resulting in torque multiplication. However, as the vehicle accelerates, a point comes when the turbine reaches near the speed of the impeller, leading to a phenomenon known as “lock-up,” where the impeller and turbine rotate at the same speed, improving efficiency. This seamless transition between the two states demonstrates the intricate engineering behind torque converter design, emphasizing the importance of both components in delivering power from the engine to the wheels with maximum efficiency.

Understanding the Lock-Up Clutch: Efficiency Meets Performance

The lock-up clutch is a critical innovation within torque converters that enhances fuel efficiency by reducing slippage between the impeller and turbine during high-speed cruising. This clutch engages when the vehicle reaches a certain speed, effectively “locking” the impeller and turbine together to prevent unnecessary energy loss. As a result, the engine operates at a more efficient rpm, optimizing fuel consumption and improving overall performance. The development of the lock-up clutch has allowed for more sophisticated torque converter designs, which contribute to better driving dynamics and improved emissions. Moreover, various modern vehicles utilize electronically controlled lock-up clutches for even finer control, enabling manufacturers to tailor the engagement based on driving conditions. Understanding the function and operation of the lock-up clutch is indispensable for anyone looking to enhance their vehicle’s performance or seeking a more fuel-efficient solution.

Performance Insights: Optimizing Your Torque Converter Experience

Tuning for Performance: Customizing Your Torque Converter

Tuning a torque converter for performance can drastically change how a vehicle functions. For enthusiasts looking to maximize acceleration and optimize their vehicle’s responsiveness, customizing the torque converter’s stall speed — the engine speed at which the torque converter begins to transmit power — is crucial. By selecting a higher stall speed, drivers can achieve quicker acceleration and more aggressive power delivery, making it a desirable adjustment for racing applications or high-performance vehicles. However, it’s essential to balance this with driving demands; too high of a stall speed may compromise daily drivability and lead to decreased efficiency in everyday driving conditions. Performance tuning also extends to adjusting the torque converter’s overall construction, such as altering blade angles and weights, which can greatly impact how it interacts with engine power. Therefore, consulting with a performance specialist or utilizing aftermarket options is vital for drivers seeking enhanced performance while navigating the complex variables of torque converter mechanics.

The Impact of Torque Converters on Fuel Efficiency

Torque converters significantly impact fuel efficiency, especially in vehicles employing automatic transmissions. By effectively managing power transfer and reducing engine load during driving, they minimize wasted energy — making the vehicle more fuel-efficient overall. The implementation of modern technologies, like lock-up clutches, has further pushed the boundaries in fuel economy by enabling a smoother transition between engagement and disengagement of engine power. Studies have demonstrated that properly functioning torque converters can improve fuel efficiency by as much as 10-15%, particularly during highway driving scenarios where constant speed is maintained. Moreover, advancements in torque converter designs, including the use of lighter materials and smarter controls, have allowed manufacturers to enhance the overall efficiency of automatic transmissions. An awareness of how torque converters function can empower drivers to select vehicles that align with their fuel efficiency goals, making informed choices in an environment where eco-conscious automotive technology is at the forefront.

Choosing the Right Torque Converter for Your Vehicle: A Practical Guide

Choosing the right torque converter is pivotal to optimizing your vehicle’s performance, handling characteristics, and fuel efficiency. Several critical factors must be considered, such as vehicle weight, engine type, intended use (daily driving, racing, towing), and desired performance characteristics. For instance, a lower-stall torque converter may be better suited for a daily driver aiming for fuel efficiency and smooth operation, while a higher-stall converter would be ideal for more performance-oriented applications. It’s also important to factor in the specifics of the engine, including its horsepower and torque output, as mismatching a torque converter can lead to inefficient performance and increased wear on drivetrain components. collaboration with knowledgeable professionals and equities in reputable aftermarket options will guide you toward making decisions that align with your performance needs while enhancing your driving experience.

The Future of Torque Converters: Innovations and Trends

Advancements in Torque Converter Technology: What to Expect

The future of torque converter technology is ripe with promise as automotive engineers continuously strive to enhance performance and efficiency. Innovative designs integrating lightweight materials and advanced fluid dynamics are paving the way for torque converters that can accomplish torque multiplication with less power loss. Additionally, the integration of electronic controls provides opportunities for adaptability and precision in performance, allowing torque converters to respond dynamically to driving conditions and driver preferences. Furthermore, the evolution of hybrid and electric vehicles demands the reevaluation of traditional torque converter roles, emphasizing the need for technologies that maximize regenerative braking while responsibly distributing power. As electric propulsion systems grow in prominence, torque converter designs will likely evolve to meet the unique challenges associated with electric power, integrating seamlessly with hybrid systems while maintaining the robust performance that drivers expect.

Comparing Torque Converters with Modern Alternatives: A Deep Dive

As the automotive industry continues to innovate, comparisons between torque converters and alternative technologies, such as dual-clutch transmissions (DCTs) and continuously variable transmissions (CVTs), are becoming increasingly relevant. Dual-clutch systems offer rapid gear shifts by utilizing two separate clutches, significantly enhancing performance and efficiency, while continuously variable transmissions provide an infinite range of gear ratios for smoother acceleration. However, torque converters still hold unique advantages, particularly in terms of low-end torque multiplication, which contributes to effortless acceleration from a standstill. When comparing these technologies, it’s crucial to consider the intended use of the vehicle, whereby torque converters may provide benefits in larger vehicles and heavy-duty applications where durability and torque handling are prerequisites. As manufacturers innovate, ongoing evaluation and understanding of both traditional and modern alternatives will prepare consumers for an evolving market where performance and technology intersect.

Sustainability in Torque Converter Design: Is Eco-Friendly Performance Possible?

With an ever-growing emphasis on sustainability within the automotive industry, innovative approaches to torque converter design are essential. Manufacturers are exploring eco-friendly materials and production methods that reduce the environmental impact while still meeting performance standards. Furthermore, the development of hybrid technologies promotes the evolution of torque converters into more efficient systems, combining them with electric components to enhance energy recovery and performance. Strategies for improving hydraulic systems also prioritize reducing fluid loss and improving the recyclability of used fluids. As consumer awareness about environmental issues rises, brands that prioritize sustainable practices in torque converter design will not only improve their marketability but also align with the shifting values of modern consumers. Sustainable development in this area is more than just an opportunity; it represents a critical component of the broader automotive goal of reducing emissions and promoting greener technologies across all systems.

FAQ

Question: What factors should I consider when tuning my torque converter? – Factors such as stall speed, overall construction, blade angles, and weights should be evaluated to achieve the desired performance balance, particularly for racing vs. daily driving needs.

Question: How do torque converters compare in performance with dual-clutch and continuously variable transmissions? – Torque converters excel in low-end torque scenarios, offering smooth power delivery, which is advantageous in larger vehicles and heavy-duty applications, while DCTs provide quick shifts and CVTs offer smooth acceleration.

Question: What role does the torque converter play in hybrid and electric vehicles? – Torque converters in hybrids and EVs are being redesigned to maximize regenerative braking and maintain effective power distribution, adapting to the unique needs of electric propulsion systems.

Question: Can a torque converter improve my vehicle’s performance significantly? – Yes, a well-tuned torque converter can enhance acceleration and responsiveness, particularly if customized to match the specific performance characteristics and driving conditions of the vehicle.

Question: What impact does the weight of a vehicle have on torque converter selection? – Heavier vehicles typically require torque converters that can handle increased torque demands, influencing the choice of stall speed and overall design to ensure optimal performance and efficiency.

Question: Are there aftermarket options available for upgrading torque converters? – Yes, there are various aftermarket torque converters that allow customization in stall speed and design, enabling performance enthusiasts to tailor their vehicle’s power characteristics effectively.

Question: How does the geometry of a stator affect torque conversion? – The geometry of the stator is critical as it influences fluid direction and force, maximizing torque multiplication and impacting both performance and fuel efficiency levels at lower engine speeds.

Question: What future trends should we watch for in torque converter technology? – Future trends include the use of lightweight materials, better electronic controls for adaptability, and designs optimized for integration with hybrid and electric systems to enhance efficiency and performance.